| Camille Bauer Applications | |||

|---|---|---|---|

| Power Generation Industry Stack Dampers | |||

Task: Their function is to handle a high temperature gas stream, i.e. the exhaust stream of a gas turbine, and direct it totally or partially to the HRSG (heat recovery steam generator) or to the bypass stack. For safety and perfect function of the plant, reliability is extremely important. The exact position of the damper is an important process parameter that has to be monitored continuously. |

Solution:

| Recommended Product:

Monitoring Damper Position |

|

| Monitoring Plant Power Consumption | |||

|

Task: |

Solution: |

Recommended Product:

Glass Plant |

|

| Power Monitoring of Induction Furnaces | |||

|

Task: |

Solution: Three values such as Voltage, total Current, phase Current, kWatt, kVAR, Active Power (Watts), Reactive Power (VAR), and Power Factor (pF) can be shown on the A210 triple display. These values allow you to monitor the running system. The A210 also has two alarm functions, which can be set up by the user for Power Factor limits. If something causes the power factor to deviate, it will trigger an alarm and indicate the actual measurements when an alarm was triggered. The two alarms can be set at different levels: low value as a warning and a higher value for a possible corrective action. This alerts the operator of a potential problem and provides a cost effective way to prevent lost production. |

Recommended Product:  Induction Furnace Power Monitoring |

|

| Predictive Maintenance of Electric Motors | |||

|

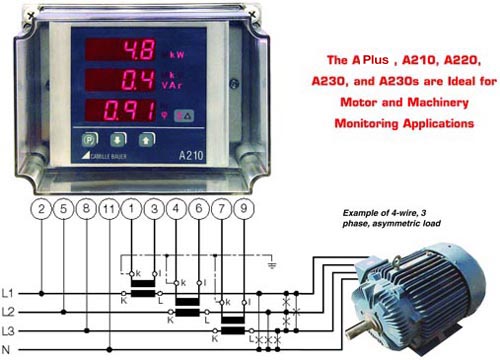

Task: As soon as the power consumption increases to 4.2 kW it may indicate that the motor bearings are going bad or some other machine component is beginning to fail. |

Solution: The A210 can be installed near the motor either in the optional NEMA 4 housing, on a DIN-rail using the optional DIN rail adapter, or in a ¼ DIN panel cutout. The A210 is connected to monitor voltage and current of the electric motor. The motor can be single phase or 3-phase, 3- or 4-wire . PT and CT ratios can be easily programmed from the front panel. Three values such as Voltage, total Current, phase Current, kWatt, kVAR, Active Power (Watts), Reactive Power (VAR), and Power Factor (pF) can be shown on the A210 triple display. These values allow you to monitor the running system. The A210 also has two alarm functions, which, for example, can be set up by the user for Watt and VAR limits. If something causes the motor power consumption goes up, it will trigger an alarm as soon as the setpoint is reached, and indicate the actual measurements when an alarm was triggered. The two alarms can be set at different levels: low value as a warning and a higher value for a possible breakdown. This alerts the operator of a potential problem and provides a cost effective way to prevent unexpected breakdowns and lost production on any type of machine operated by an electric motor. |

Recommended Product:

Monitoring Power Consumption of a 3-Phase Motor |

|

| Testing Incoming and Rebuilt Electric Motors | |||

|

Task: |

Solution: The A210 is connected to monitor voltage and current of the electric motor. The motor can be single phase or 3-phase, 3- or 4-wire . PT and CT ratios can be easily programmed from the front panel. Three values such as Voltage, total Current, phase Current, kWatt, kVAR, Active Power (Watts), Reactive Power (VAR), and Power Factor (pF) can be shown on the A210 triple display. These values can be wriiten down or logged with the optional EMMOD datalogger. |

Recommended Product:  Electric Motor Repair |

|